[one_half padding=”0 20px 20px 20px”]

Texture profile

Improved high nickel-chromium centrifugal composite casting roll production process, the outer layer to increase the V, W and other strong carbide forming unlimited chilled cast iron, the core element of the high-strength ductile iron.

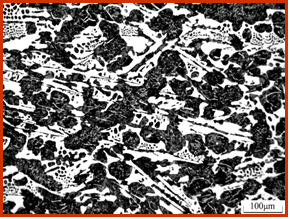

Outer bainite matrix tissue contains large amounts of eutectic carbides, small MC type carbide uniformly dispersed in the matrix, carbide content of about 25-35%. At the same time the organization also distributed Free State 1-3% graphite.

By optimizing the heat treatment process to ensure the roll has better stress level and suitable hardness.

Main application

- All kinds of strip mill finishing after the period of work roll

- The front end portion of the stainless steel finishing mill work rolls

- The heavy plate mill roughing, finishing work roll

- Mill bearing rollers

Performance Characteristics

- The texture makes a lot of carbide rolls have good wear resistance and surface quality, quality assurance rolled.

- Mill situation for different design optimization carbide and graphite content ratio, improve roll performance.

Microstructure

[/one_half]

[one_half_last padding=”0 20px 20px 20px”]

Performance Indicators

| Performance Index | Units | Numerical Value |

| Hardness | HSD | 70-83 |

| Tensile strength | MPa | 420-620 |

| Thermal conduction | Wm℃.at 500℃ | 18-20 |

| Swell factor | 10-6/℃ | 11-13 |

| Elastic modulus | 104MPa | 17-19 |

| Poisson’s ratio | – | 0.23-0.28 |

| Density | Kg/m3 | 7450 |

| Specific heat capacity | J/g℃ | 0.54-0.70 |

Hardness

[/one_half_last]